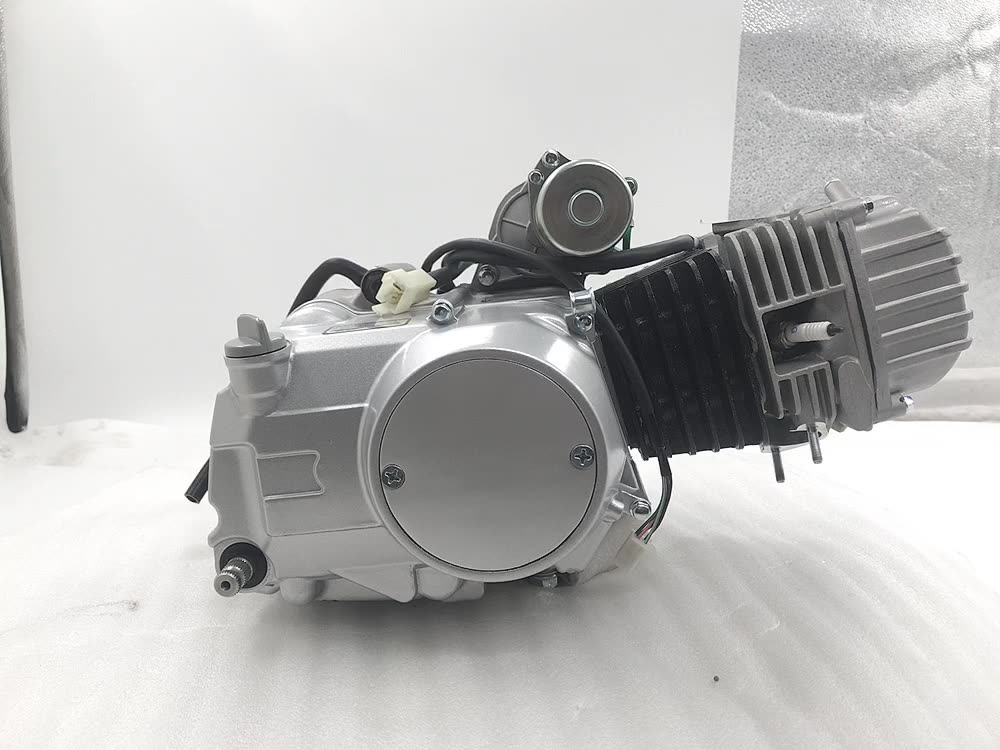

Classic heavy loading tricycle 200CC/250CC/300CC

200 air-cooled machine, 40*80 keel pickling and phosphating large frame, external 5+2 steel plates,06 one-arm shock absorbers,

5.0-12 three-wheel ordinary tires, 180 brake drums for automobile rear axles,large toolbox , 1.8m*1.3m full pattern small engineering electrophoresis cargo box

9A battery Five sheep second generation +40 Five sheep three generations +80

_62629.jpg)

_19563.jpg)

_25219.jpg)

_12484.jpg)

_93637.jpg)

_88642.jpg)

_37882.jpg)

_99720.jpg)

| Engine | 200cc,AIR-cooling |

| Chassis | 40*80 |

| Rear- Axle | Intergral booster drum,Φ180 |

| Operating model | Handle (optional Car Steering Wheel) |

| Front Shock Absorber | Hydraulic spring(Four) |

| Rear Spring Leafs | 5+2 |

| Front Brake | Drum |

| Rear Brake | Hydraulic |

| Wheels Type | Five |

| Front/Rear Tire | 5.0-12/5.0-12 |

| Cargo box type | Heavy duty |

| Cargo box size (L*W)(M) | 1.8*1.3 |

Applications

Agriculture. Tourism. Transportation

1. It can be used as a rural transport package for grain, rice, potatoes, fish and other crops.

2. It can be used in rural transportation constructions such as bricks and cement. River sand, building materials, etc.

3. It can be used for the transportation of natural stones such as coal and minerals.

4. It can be used to transport timber and logging tools in the forest

5. Usable short-distance passenger transportation

6. It can be used to transport all kinds of crops, building materials, food materials, wood, stone, appliances, tools, furniture, garbage, patients, etc.

7. It can be used as a necessary means of transportation in low-income families.

We provide CKD, SKD tricycle. Any special requirement for the packing, please contact us.Each model materials will be packed separately the packing system will follow the ISO standards for packing.

1. Material technology: We will select 5-10 products that meet our standards from 100 steel products. As for the remaining material suppliers, we will supply other second and third-tier brands of factories, only those that meet our previous thickness, size and The talents of the materials have passed our screening, so our selection rate is 5%-10%. And our frame production line is composed of 18 crafts.

2. Pneumatic fixtures are also used in our production process to ensure stronger welding strength and better consistency. The production of tooling refers to automobile standards and has obtained a number of patents. 360 reverse tooling to weld the frame to ensure the reduction of missing welding.

3. Car-carriage welding: 90% of carriage-car welding is welded by CNC robots, with better quality and smoother and more beautiful welding points.

4. Invest 3 million yuan to build a shot blasting workshop to ensure that there are no uneven areas before the paint, and the surface of the frame and the carriage after the paint is smooth and smooth.

_82552.png)

_18449.png)

_60002.png)

_49691.png)

_63181.jpg)